VAC5 - HIGH PRODUCTION VACUUM

POUCH SEALER

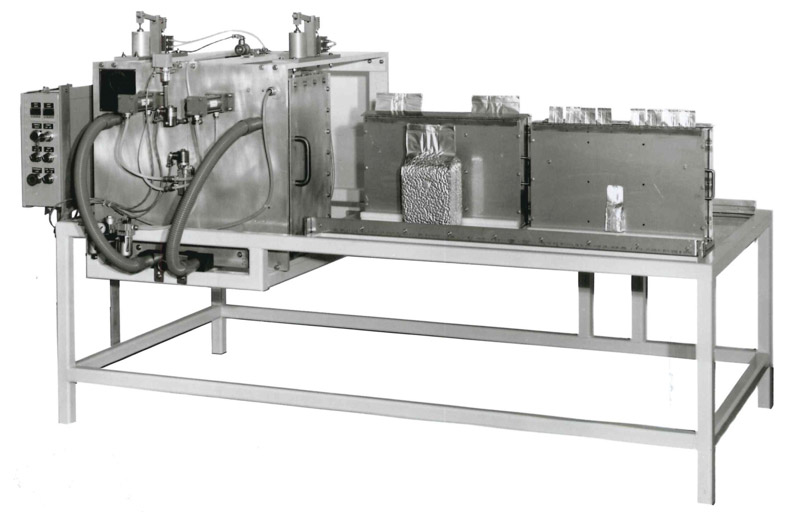

The VAC5 vacuum chamber pouch sealer is made to meet high production pouch vacuum sealing requirements with premade pouches. The VAC5 seals as many as ten packages per cycle and can be operated at up to 3 cycles per minute. The VAC5 will work with pillow packs, four side seal, stand up bags and side gusseted square bottom bags. The latter are produced as vacuum bricks with squared sides. The VAC5 can be adapted to gas back-flush to produce soft packs. The vacuum level is adjustable.

Carrying cassettes hold from 1 to 10 pouches per cycle depending on the size. Two cassettes are provided to allow unloading and reloading of one while the other is in the vacuum chamber. The vacuum and seal operation usually takes 12 to 15 seconds. The output rate depends on the rate at which the bags are handled by the operator(s).

Change parts are required for each package size. Changeovers can be made in 5 minutes. The VAC5 includes a 5 HP vacuum pump, PLC controls with touchscreen operator interface, a large stainless steel work table and a welded frame coated with a food grade baked epoxy.

VAC5 - SEMI-AUTOMATIC

VACUUM SEALER

Package Specifications

Maximum bag thickness: 6” (152 mm)

Maximum product height: 14” (356 mm)

Cycle Capacities

2” or less (51 mm)

Up to 2.1” (53 mm)

Up to 2.4” (61 mm)

Up to 2.7” (69 mm)

Up to 3.2” (81 mm)

Up to 3.9” (96 mm)

Up to 4.9” (120 mm)

Up to 6.5” (165 mm)

Up to 9.9” (242 mm)

Up to 20” (508 mm)

10

9

8

7

6

5

4

3

2

1

Options

In-seal code dating. A suitable filler can be supplies mounted on the side of the VAC5 frame.

For information on fully automatic vacuum pouch packaging on vertical bag form fill seal machines contact General at the phone number or email address listed below.